Stoll Front End Loaders

Stll Front Eng Loaders

Full Power.

No compromises.

The strongest front loader from STOLL. Full Power. No compromises. A front loader that is unrivalled.

Be won over by its sheer power, ease of use and impressive service life – made in Germany.

Our intelligent designs provide you with a variety of comfort features exclusively from STOLL.

Top class.

Made in Germany.

German engineering is known all around the world for its high quality, performance and reliability. That is why we develop all STOLL front loaders with precisely these values in Germany.

They combine state-of-the-art technology with innovative solutions – and this is exactly what we expect from high-quality German products.

Experience the full power of the STOLL ProfiLine. The amazing best values in all areas ensure the highest quality in lifting capacity and lifting height, stability and loading speed.

In addition to this, the individually selectable accessories from the ProfiLine fit in perfectly with your needs as a farmer or contractor. True professionals for professionals.

Full power – slim design.

The ProfiLine FZ front loaders are made of fine grain steel – Advantage: High stability and torsional rigidity, plus a slim and lightweight construction.

The lifting arm boom is bent from a single piece of steel.

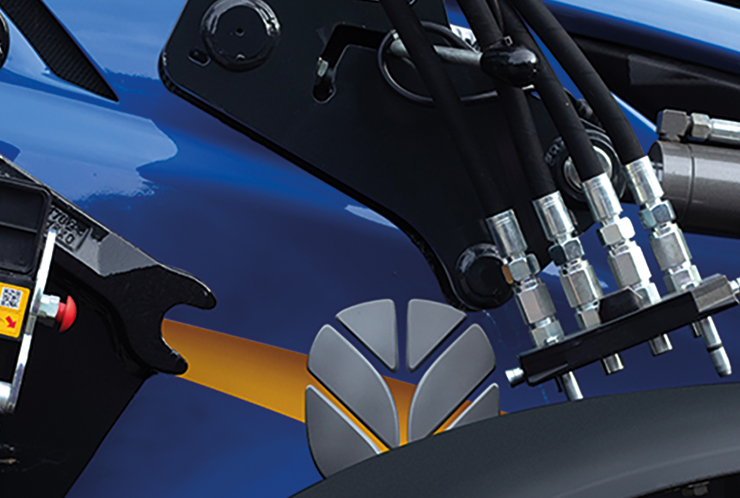

The control rods are installed inside the beam. All the hydraulic lines are well protected but can be freely accessed under the beam.

The tare weight of the front loader is low making it extremely powerful. Having less weight significantly reduces the loading on the front axle of the tractor, thereby extending its service life.

In order to avoid the need to regularly replace the hose lines by the lifting arms in accordance with DIN 20066, we use wear-free steel hydraulic pipes instead.

Less load on the tractor and a greater accurate fit.

The attachment components can be installed perfectly on all common tractors – that is why the designers at STOLL individually adapt every tractor model.

Reduced load on the front axle thanks to the optimal positioning of the attachment components close to the driver’s cab.

Often the windscreen can only be opened together with a STOLL attachment component.

The attachment components fit perfectly as they are individually adapted to each tractor.

Z-kinematics – best view and high performance.

The rods of the mechanical parallel guide are located in the lifting arm booms – the basis of the Z-kinematics.

This frees up the view for the driver. No parts above the lifting arms obstruct or are in the way. Another benefit: The front loader can also be mounted closer to the driver’s cab – result: Reducing the load on the tractor by optimally positioning the attachment components.

Front loaders with Z-kinematics have even greater lift capacities and breakout forces. There is no loss of lifting power.

Ready to use in under 2 minutes...

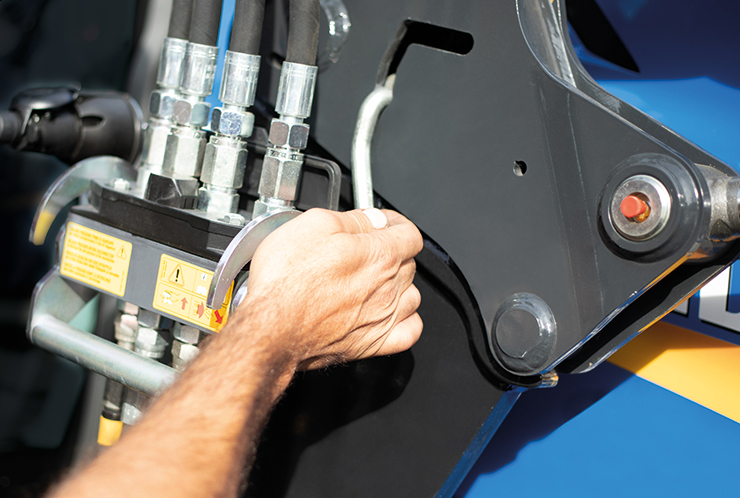

When driving in, the front loader slides along the attachment until the locking pin meets the upper end of the connection support.

With the Hydro-Fix all hydraulic lines can be connected to the tractor at the same time. The front loader is lifted slightly to hold the locking pin in position in the catch hook of the connection support.

The locking lever is pressed downwards and the front loader securely held in position on the attachment. Then the front loader is raised higher.

The parking stands can be folded in and out without tools.